FOR RUBBER INDUSTRY

Is a Russian company which is specialized in recycling innovative technologies for the rubber industry.

is ready to offer to his customers the following product with the application properties which you will not find in any other solution proposed for the rubber industry market now.

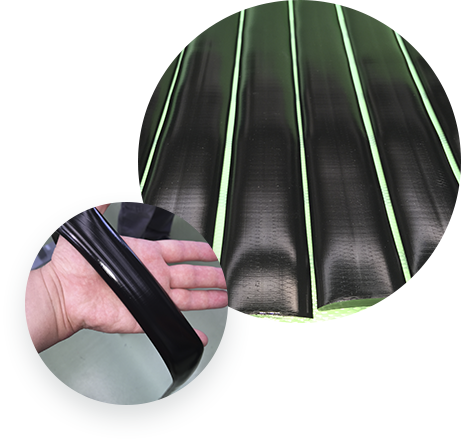

Butyl rubber compounds produced by GREEN RUBBER company, are used as an additive in rubber compounds instead of butyl rubber (up to 60%) for the manufacturing of different industrial rubber goods. Besides our butyl rubber compound can be used by itself (independently) to produce rubber compounds which are used for the manufacturing of corrosion resistant coatings, sealing and waterproof coatings, mastics and some rubber parts. Our butyl rubber compound is also well-suited for the production of thin-walled parts and parts with smooth glossy surface.

- Homogenous structure

- No impurities

- Odorless (cold product)

- Absolutely smooth surface

Butyl compound is shipped in form of plates (5 kgs/plate). Butyl compound plates are packed in carton boxes of 25 kgs. Carton boxes are put on wooden pallets (up to 40 carton boxes on each pallet). The final weight of a wooden pallet with the product is up to 1000 kgs. Besides we can propose to you alternative packages if it is required.

Optimization of production process

Hight quality materials

Minimal effects on the environmental

Good price

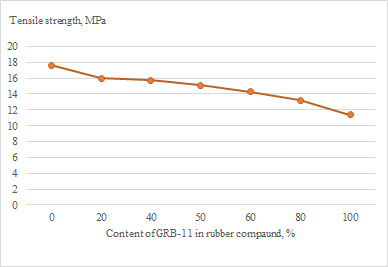

Pic. 1 GRB-11 effect on tensile strength

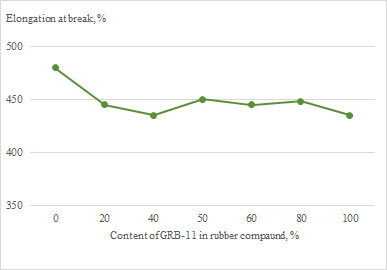

Pic. 2 GRB-11 effect on elongation at break

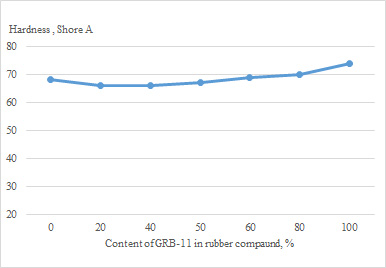

Pic.3 GRB-11 effect on hardness (Shore A)